Laboratory for Catalyst Characterization (LCC)

Kind:

Chemical investigation of porous catalysts and electrode structures

Country:

Germany

Technology

Electrochemical energy storage

Chemical energy storage

Organisation:

Forschungszentrum Jülich

Availability:

By appointment

TRL Level:

1-3

Download the full document

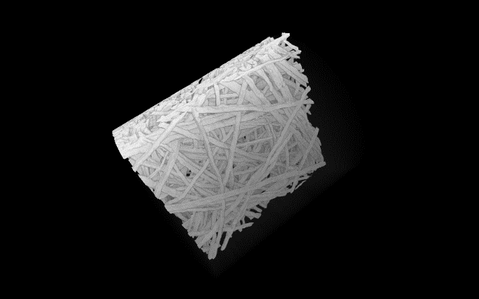

1. The Zeiss Versa 420 nano X-ray computer tomograph depicted above allows non-destructive imaging of structures and materials in optically non-trans¬parent objects over four size scales, i.e. 500 nm to ~1 mm. X-ray tomography allows the 3D reconstruction of e.g. the porous transport layers in electrolyser and fuel cells. Information on the pore size/coverage of the layer before and after electrochemical testing can be gained. This enables e.g. studies on degradation (agglomeration of particles), on the interaction between the porous transport electrode and the CCM and catalyst utilization. In addition to the measurements also the image processing and evaluation of the obtained tomographic data can be performed.

The sample stage is operable up to 15 kg load. Samples up to a maximum size of 10 x 10 x 10 cm are can be investigated (depending on x-ray trans-mission/absorption). There is a labyrinth for electric connections and other media (gases, liquids) up to 80 mm diameter, allowing e.g. in-situ measurements on electrochemical cells.

2. The reactor system, which is shown in the picture above can be used to investigate interactions between gas molecules and a solid catalyst. This is done by injecting an extremely narrow gas pulse into one end of a micro-reactor and continuously evacuating the other end. Hereby, gas transport through the catalyst is governed by Knudsen diffusion, which minimizes the number of collisions between molecules in the gas phase. A pulse valve assembly is installed in the system through which the narrow gas pulses are injected into the micro-reactor, which is located below the pulse valves. Furthermore, the TAP system contains a mass spectrometer chamber, in which the reactor effluent is analyzed. Below the mass spectrometer, there is a liquid nitrogen chamber, which ensures that no oily substances from the high speed vacuum system below the liquid nitrogen chamber can enter the mass spectrometer chamber. The cabinet on the left hand side in the picture serves for supplying different gas blends to be investigated, whereas the cabinet on the right hand side contains all necessary control units. The interaction between the gas molecules and the catalyst surface gives insight into elementary steps of the reaction and reaction intermediates and allows for the calculation of kinetic data such as rate constants of adsorption or desorption or reaction rate constants.